Victoria Gate was a £165 million scheme that forms part of the new 53,400m2 Victoria Leeds shopping destination, creating the largest premium retail space in Northern England. Designed by architects Acme, the development is a striking nod to the city’s rich merchandising and textile history and was voted the best shopping centre in the world.

Design Criteria

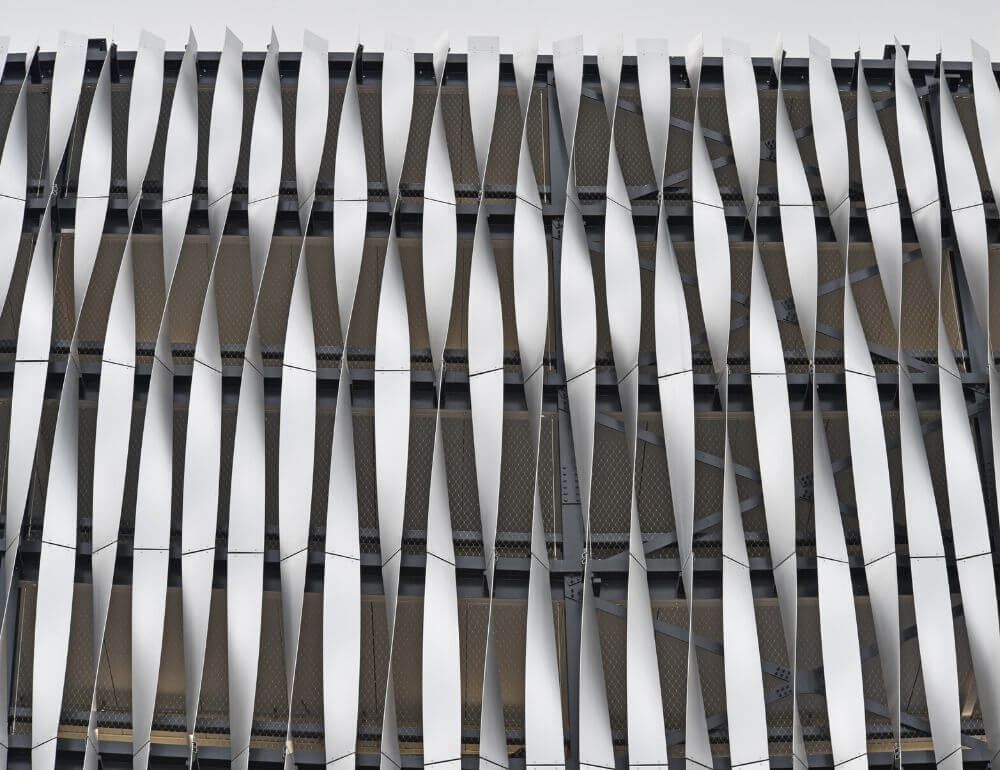

Acme had a complex design brief for the adjoining car park at Victoria Gate. The façade was designed to mirror the unique diagrid etched concrete of the centre. With an outstanding track record, Spanwall was appointed by Maple to help deliver the façade element for contractors Sir Robert McAlpine. A key feature was the creation of a bespoke solution to ensure the facade would perfectly replicate the centre, seamlessly blending into the building. Spanwall designed a twisted fin façade that would bring the architect’s vision to life – however the biggest challenge was that the technology to create these fins did not exist.

Manufacturing Excellence

Spanwall manufactured a machine at their state-of-the-art factory in Carryduff, Northern Ireland, that enabled them to twist the aluminium panels into a series of partial twists, creating a stunning architectural façade made up of a series of fins twisted at various angles to give the appearance of diamonds. The result was a highly engineered product that was truly fit for purpose and the very best in both form and function.

The product was presented in a natural anodised state, which gives the façade a reflective surface. As the light hits the façade, this creates colour. This was a large-scale complex project and as construction took place within a live site, planning, logistics and liaison were crucial to ensure the fins were ready for handover. This award-winning product has received critical acclaim and is a true example of the manufacturing abilities at Spanwall.