The Titanic Visitors Centre in the heart of our home city of Belfast is arguably the most iconic project to feature and showcase Spanwall’s expertise in sheet metal fabrication.

In 2012 costing £100 million, the Museum which is the largest man-made tourist attraction in Northern Ireland and part of the ongoing £7bn Titanic Quarter development for Harcourt Development opened its doors, 100-years after the ill-fated steamship left Cobh for New York.

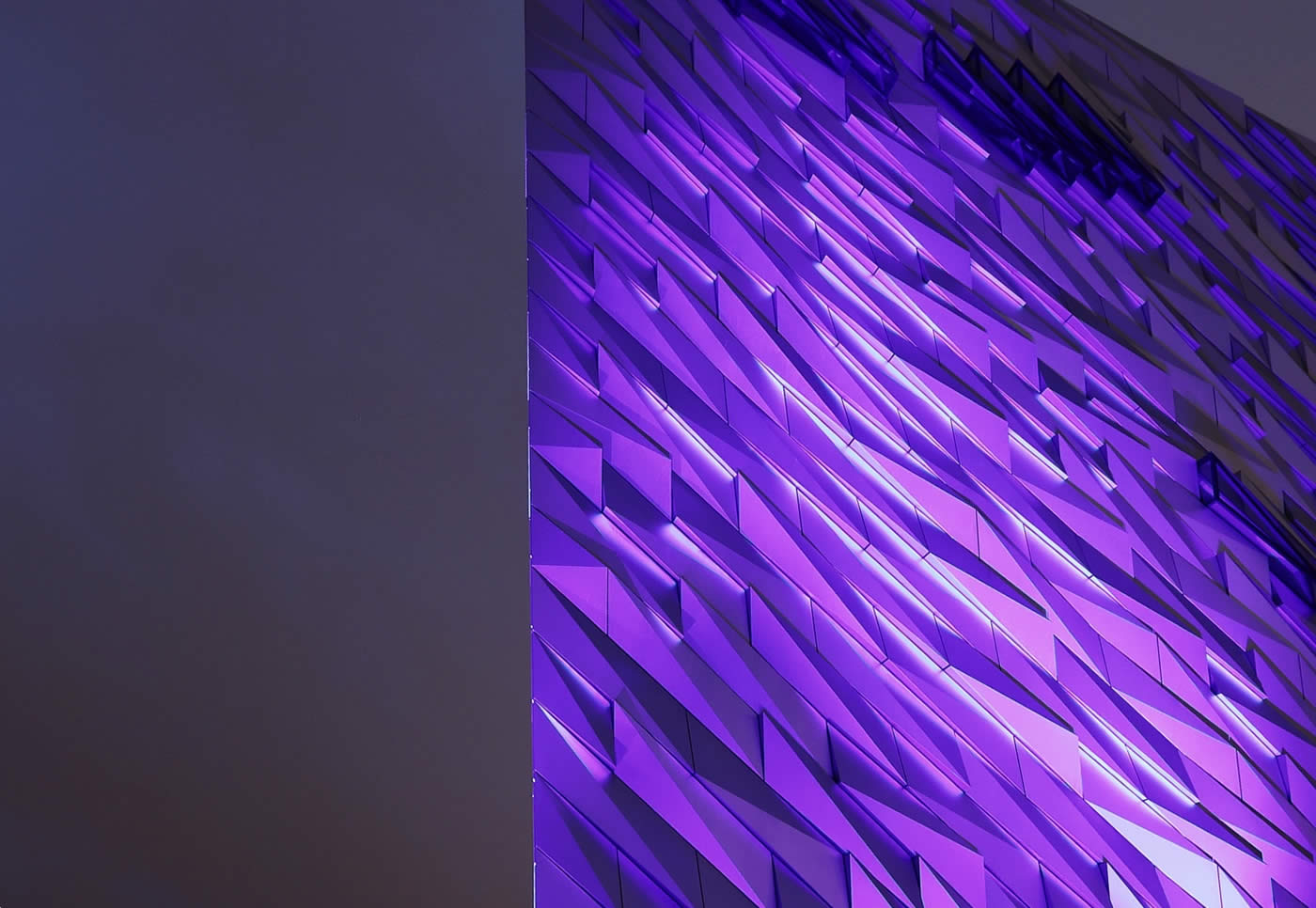

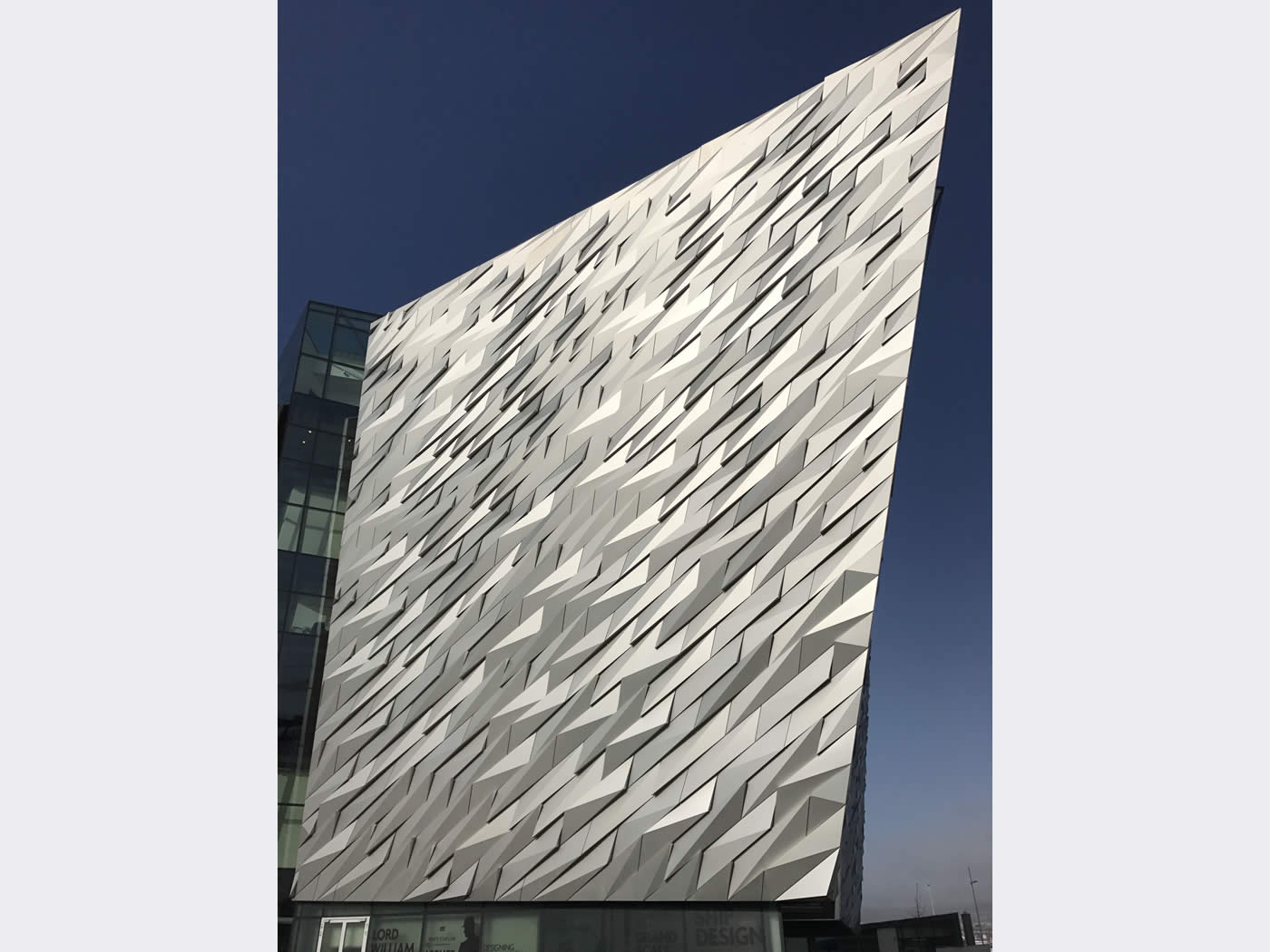

From a distance the 3- dimensional rainscreen panels manufactured from almost 120 tonnes of 3mm J57S Aluminium look to be two-tone coloured but were all anodised in natural silver and covers the four-pointed 28-metre-tall hulls of this maritime museum. With approximately 2,000 different panels this was a challenging project. Spanwall worked closely with Belfast-based TODD Architects at the early concept design stage and were able to simplify the panel design and layout to create 6 standard geometrical shaped aluminium panels and one, very special one-off, panel for all the elevations. Spanwall was also able to incorporate it’s RF50 Rainscreen carrier system into the design for the installation. Most panel measure 4-metres on the diagonal. Spanwall achieved the original concept and vision for the irregular panel facade while keeping the costs for the geometrically complex shapes within the project budget. Installation was carried out by German specialist building envelope contractor Metallbau-Frueh.

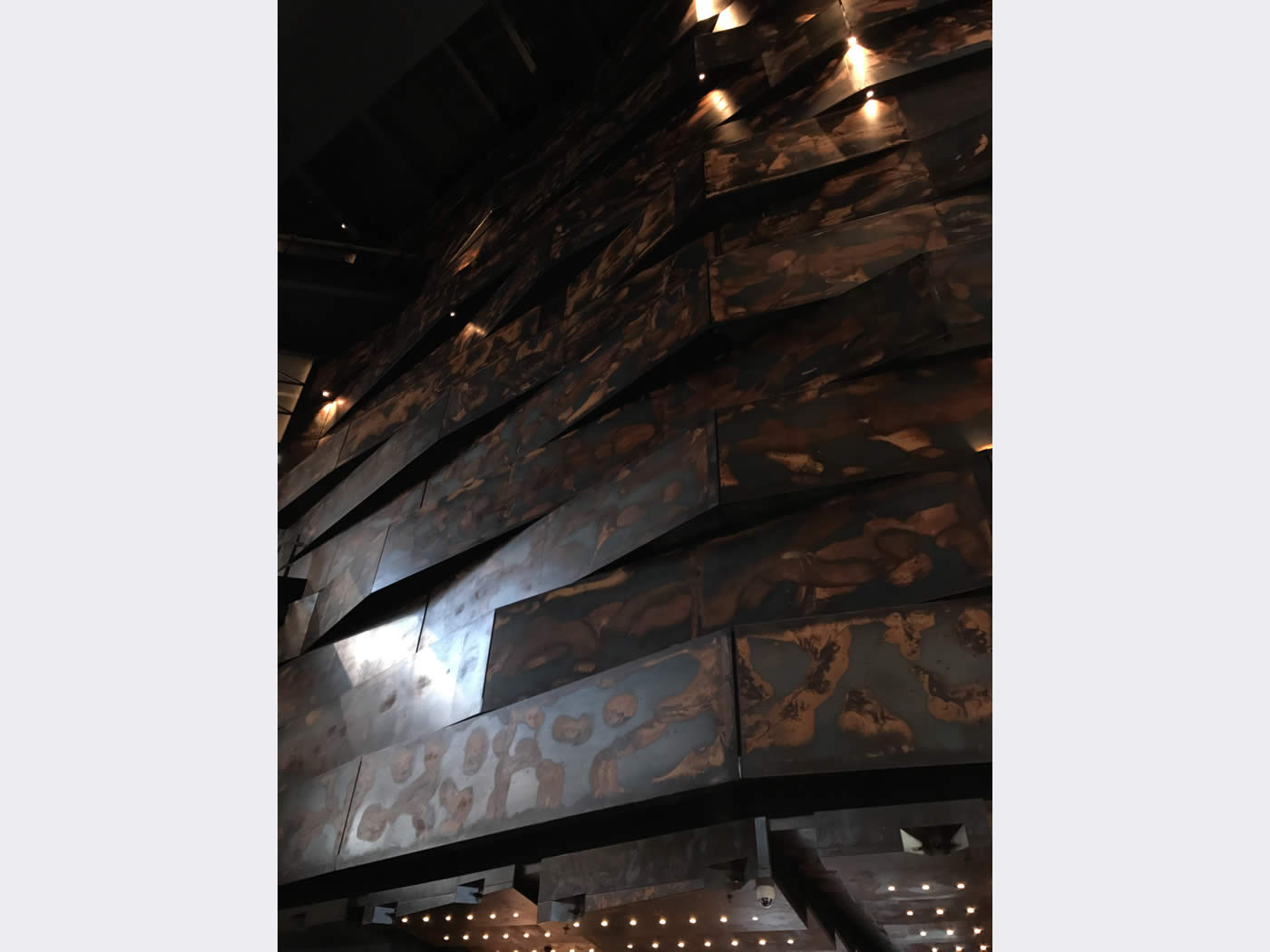

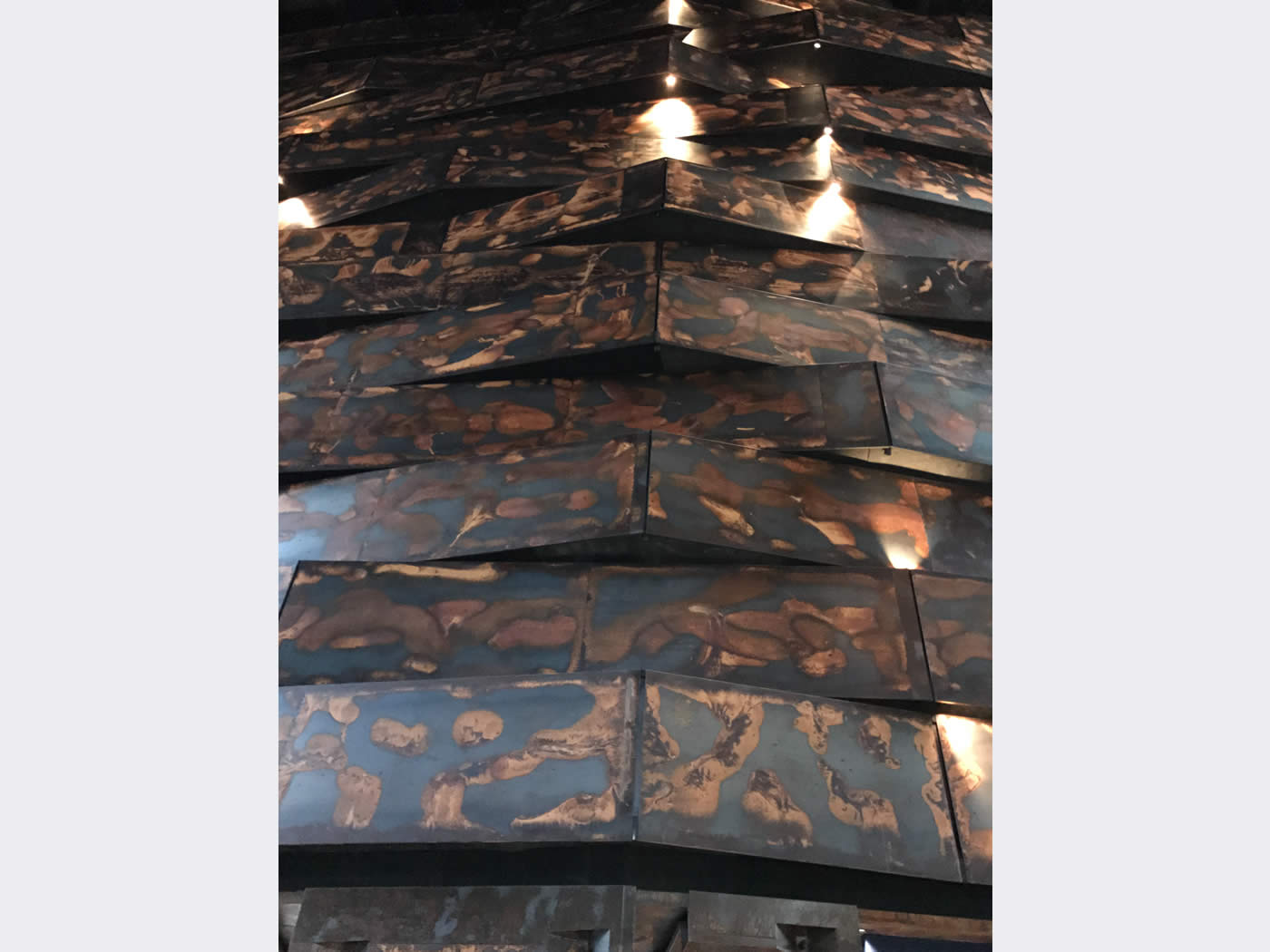

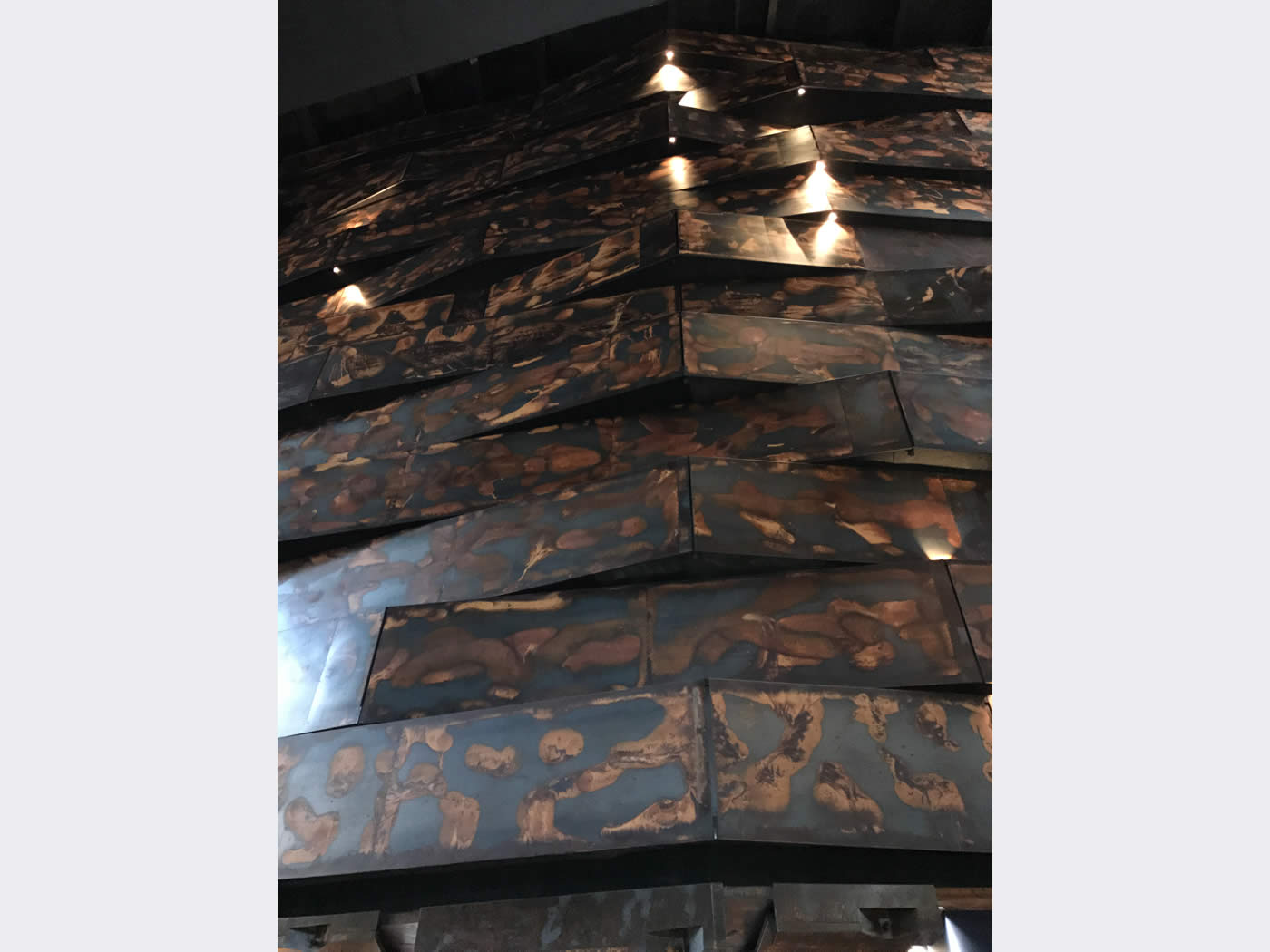

Spanwall also worked on the interior where custom-rusted steel sheets were used for walls and ceilings, with the undulating system of steel plates having a patina in keeping with the site’s ship-building heritage.

The building secured its own record with more than 4 million visitors to date from all over the world.