6-Nov-2024

In this article, we interview David Clark, Managing Director of Spanwall Facades and look at his view of the façade sector, why digital innovation and lean manufacturing are central to Spanwall’s business strategy and how the business is well positioned to undertake more reclad and remediation projects.

It is now a year on since your appointment as MD. What are your reflections?

There are clearly significant challenges facing the construction industry in the UK and in Ireland in a post-pandemic economy. There is considerable uncertainty in the wider market, but we have worked hard in the last two years to make the business leaner, smarter and stronger.

We are well advanced on our digital journey which has increased efficiency enormously, particularly in manufacturing, which is good for our customers and our investors.

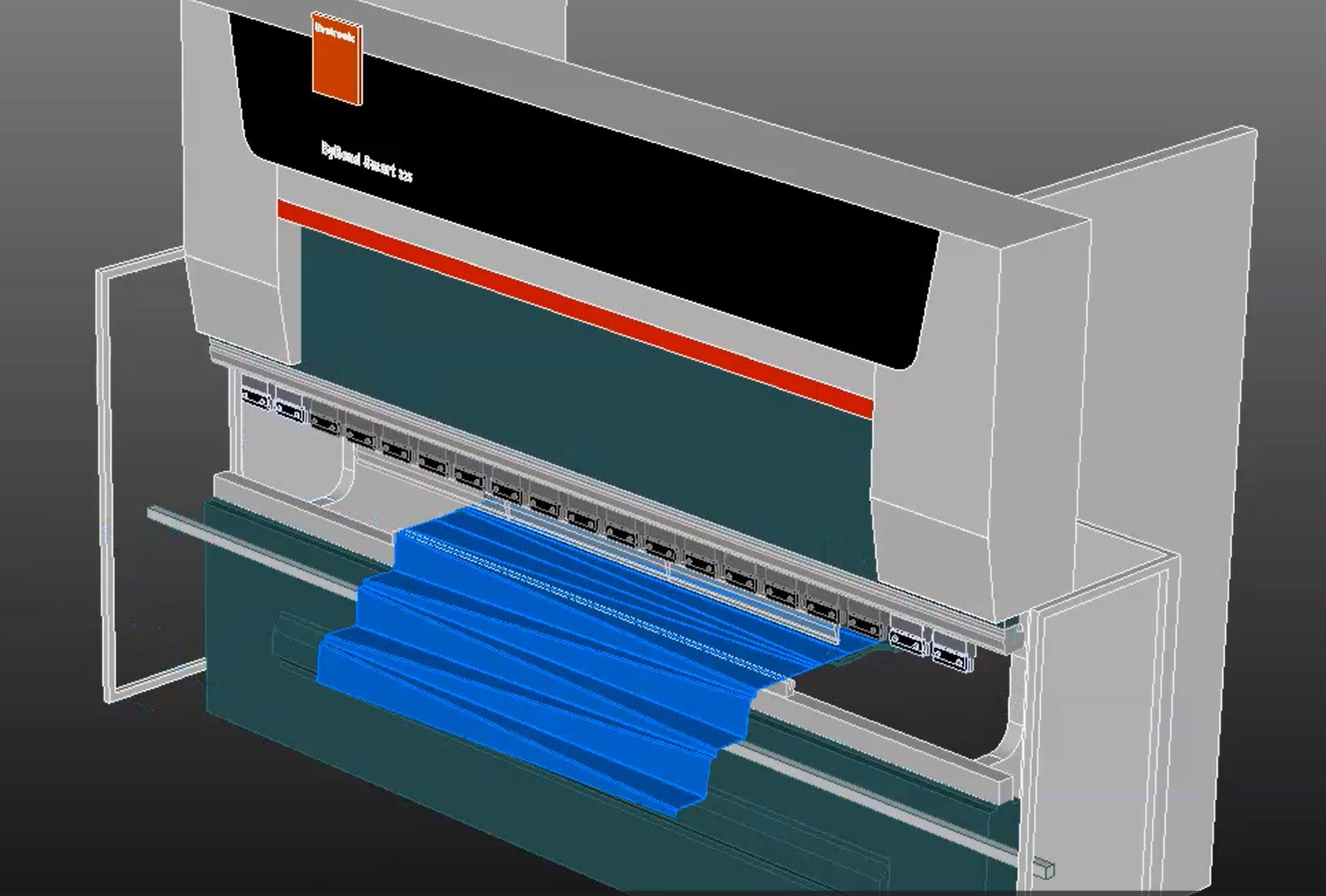

Our factory has been reorganised and modernised. We have introduced new processes, state-of-the-art manufacturing technology and have the technical capabilities in place to more efficiently produce our range of metal rainscreen facade systems - with all the benefits of repeatability and standardisation.

We have optimised materials use and have processes that ensure consistent quality, cost efficiency, robust testing, and shorter lead times.

We have recently launched a brand-new production line for our RF50-FR cladding range, which is very much geared towards the reclad market, to help bring more buildings up to the new safety standards.

What has been your professional journey before becoming MD of Spanwall?

My career at Spanwall began in 1997 when I joined the business as Design Technician before progressing to the role of Design Manager. I was involved at the very start of Spanwall’s digital journey, implementing 3D CAD for the design of metal rainscreen cladding and improving the design to manufacture workflow.

After five years, I was keen to broaden my experience, working on the design of specialist metalwork and on some high-profile projects, such as King’s Cross Station and the London 2012 Olympics. I then moved into offsite construction, becoming Manufacturing Director for one of the UK’s leading modular building companies.

I re-joined Spanwall in 2021 as Manufacturing Director and was appointed Managing Director in 2023.

My career has given me the opportunity to continually expand my knowledge in the design and manufacture of architectural metalwork, as well as in offsite manufacturing. I remain committed to design, R&D and to applying the latest digital technology to achieve efficiency improvements at each stage of the product and building cycle, to the benefit of our customers.

What are Spanwall’s growth plans?

We offer a full range of metal cladding solutions to specifiers, developers and building owners, and to our customers – specialist façade contractors.

Spanwall has built an enviable reputation over the last 50+ years for developing advanced technical solutions to deliver really complex metal rainscreen façades to create world class buildings and award-winning architecture.

This bespoke work is still an important part of what we do in the UK, Ireland and internationally. However, there is a huge opportunity to grow the market for our range of architectural metal cladding products, which offer such a high level of design flexibility at volume.

There are very few metal rainscreen specialists in the UK that have the technical capabilities and manufacturing resources to undertake the range of projects that we now can.

.png)

What are the key issues facing the facades and cladding sector?

Fire safety is now the single biggest issue, not just in facades and cladding, but across UK construction. As an industry, we have to ensure the entire supply chain – building designers, contractors, product manufacturers, regulators, installers and specialist contractors – face up to the stark findings and recommendations following the Grenfell Tower Inquiry.

Sustainability and the drive to net zero are also vitally important. The building envelope is a key element of every project – whether existing buildings needing upgrading or new build developments. ‘Smart’ façades will help to deliver more energy-efficient buildings with much less impact on the environment. We are passionate about playing our part in that journey.

Lastly, and as with any business in construction, the rising cost of materials remains a constant challenge.

What are your strategic priorities?

Our RF50-FR fire rated range is our highest volume product and has huge growth potential.

This system creates fire rated metal rainscreen façades with concealed fixings. It is a rigorously tested premium product that is ideally suited to the reclad market – from hospitals and schools to high-rise housing and commercial office buildings.

It is estimated that there are well over 4,000 residential buildings of 11m high or more in the UK with unsafe cladding – and only around 2,000 of those remediation projects – less than 50 per cent – have been started or completed. And recent figures suggest these figures are likely to be much higher.

Our recently commissioned production line specifically for the RF50-FR metal rainscreen system will help meet the increase in demand that we are predicting in the reclad market.

This line uses the latest robotic technology and, together with two new CNC machines, a stud welding machine and other new production technology, it represents an investment of around £1m for Spanwall.

We now have the products, processes, technology and capabilities to efficiently produce metal rainscreen cladding at the scale required and to help bring existing buildings up to the new standards that are so vital to keep their occupants and our communities safe.

Spanwall recently won a national manufacturing award for digital innovation. Why is digital technology so important?

Our focus in the first phase of Spanwall’s digital transformation has been to improve workflows and efficiency, from design to manufacturing. This is an industry leading initiative, not just in the façades sector, but in British industry, as our recent award has demonstrated.

Advantages include single item identification and tracking which give our customers a new level of traceability.

Lead times have been reduced and there are cost reductions of around 80 per cent for digital prototyping of metal rainscreen components, prior to cutting material in the factory. Machine set-up times for production runs have also been reduced by up to 50 per cent.

The next stage will be to leverage and integrate this digital functionality and to enhance efficiency across all operations, such as estimating, financial management, scheduling, quality control, preventative maintenance of our manufacturing equipment, and health and safety in our factory.

Ultimately, we plan to take customer information in a digital format and that will speed up the front-end sales and estimating functions, before moving the projects through design and manufacturing.

How are you addressing the journey to net zero?

The process is ongoing. This year we have launched our sustainability strategy which has set clear KPI targets. We have appointed a Sustainability Manager and have introduced monthly sustainability and factory audits to monitor, capture and feed data back to the leadership team to facilitate decision making.

Our investment in new manufacturing technology, such as advanced CNC cutting machines and digital design for manufacture, will ensure that we minimise material waste at every stage of the production process.

We are also keen to play our part in improving the thermal efficiency of building envelopes as well as the amount of recycled material content and recyclability to minimise environmental impact.

R&D remains vitally important to keep our product offer moving forward to help customers, contractors, developers and building owners meet their net zero commitments.

Offsite construction and MMC is another means of improving sustainability in construction. By maximising assembly offsite in a controlled factory environment, we can minimise vehicle movements to site and reduce material waste and product damage on site.

Our FP30 system, which uses interlocking joints, lends itself well to offsite manufacturing and allows us to deliver more complex subassemblies to customers.

Where do you see Spanwall in the next five years?

We can now offer a full package of metal façade systems to our customers – from bespoke solutions for more complex projects, to our comprehensive range of rainscreen products in a wide variety of anodised and polyester powder coated finishes. Our aim is to be the leading fabricator for metal rainscreen cladding in the UK and Ireland.

With our strong leadership team, backing from investors and commitments to innovation, digital technology and building safety, we feel we are well placed to help our customers and specifiers address the wider challenges facing the construction sector and to increase Spanwall’s market share in the façade industry.